Preparation

Incoming and interstage heat treated coils of raw material or wire are cleaned chemically and coated with Lime, Borax, Phosphate, Stearate, Copper or Bonderlube ready for the next stage of production. Incoming hot rolled bars are shotblasted and in line lubricated.

Heat Treatment

Materials can be spheroidise or machinability annealed, normalised, using atmosphere controlled or batch methods, hardened & tempered and/or stress relieved.

Wire Drawing

Coils up to 3 tonnes, Crack detection size range, 10.00 – 70.00mm, Ultrasonic Inspection, size range, 10.00 – 50.00mm, 4.00 – 35.00mm round or equivalent shapes.

Cutting to Length

Spinner straightening and cutting to length for round wires up to 35mm. Shaped wires in the equivalent round range 5 – 16mm can be cut to length from coils.

Bar Drawing / Reeling

Up to 75mm in rounds or equivalent cross section shapes.

Short Lengths

Available using sawing or cropping equipment to precise tolerances.

Chamfering

One or both ends, 8 – 60mm or equivalent rounds.

Crack Detection

In or offline for bars, 7 – 70mm or equivalent rounds, in line only for coils.

Unltrasonic Testing

An offline process, including crack detection and laser measurement for bars in the range 7 – 50mm or equivalent rounds.

Bar Grinding

Full size range

Bar Peeling

20-80mm dia.

Facilities

Kiveton Park Steel has a wide range of production facilities, on one site, for the production of round and shaped section wire and bar in a variety of carbon, engineering and alloy steels available for both prime and sub contract manufacture.

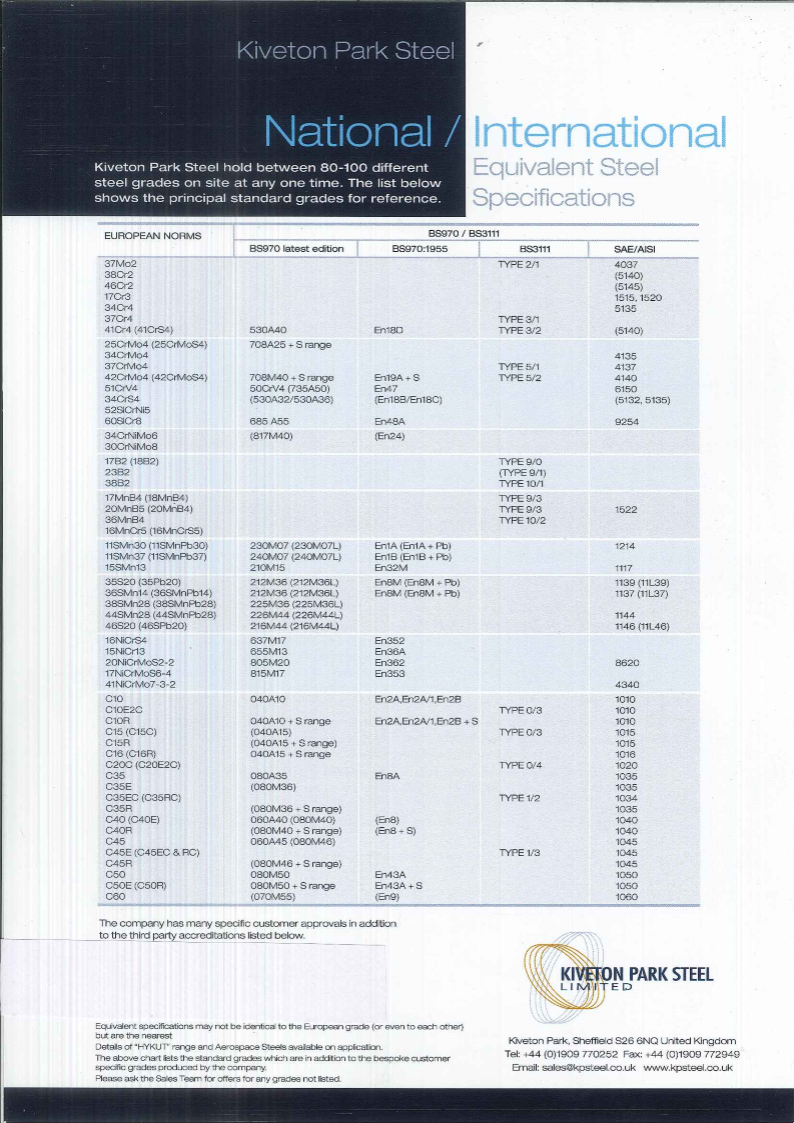

Please click the PDF on the right to view a comparison of equivalent international standards for material composition, in addition to which, the company has an exclusive range of heat treatable alloys traded under the name “HYKUT” with improved machinability characteristics. Where customers require very straight, stress free products the company has also developed specific processes to meet these very demanding applications.

In many instances Kiveton Park Steel works closely with both raw material

sources and end users to develop bespoke specifications covering special steel analyses and processes / process controls to establish unique supply chains for critical products.The facilities listed below provide details of the installed capacity which is also available for the hirework of standard or special materials including stainless steels and nickel alloys.

In many instances Kiveton Park Steel works closely with both raw material

sources and end users to develop bespoke specifications covering special steel analyses and processes / process controls to establish unique supply chains for critical products.The facilities listed below provide details of the installed capacity which is also available for the hirework of standard or special materials including stainless steels and nickel alloys.

1. Commercial Offices

2. Works Offices

3. Warehouse

4. Engineering Centre

5. Wire Drawing

2. Works Offices

3. Warehouse

4. Engineering Centre

5. Wire Drawing

11. Covered Raw Material Storage

12. Cleaning & Coating

13. Batch/Continuous Heat Treatment

14. Technical Centre

15. Weighbridge/Security

12. Cleaning & Coating

13. Batch/Continuous Heat Treatment

14. Technical Centre

15. Weighbridge/Security

6. Bar Finishing/Offline NDT/U/S Testing

7. Bar Drawing

8. Cutting to the Length/Grinding

9. Wire Drawing

10. Coil-Bar Drawing

7. Bar Drawing

8. Cutting to the Length/Grinding

9. Wire Drawing

10. Coil-Bar Drawing

Kiveton Park Steel Limited, Kiveton Park, Sheffield, UK, S26 6NQ. Tel: +44 (0) 1909 770252 Fax : +44 (0) 1909 772949